Concrete grinding machines use rotating heads to smooth and level the concrete surface. The process is called ''diamond grinding'' when the abrasive discs contain diamond particles. However, tungsten carbide discs can also be used, especially when thick membranes and glues need to be removed.

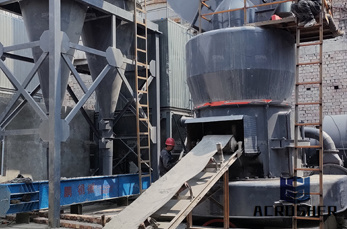

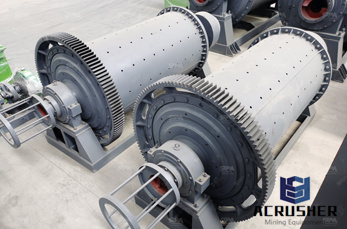

Find here Cement Grinding Plant manufacturers, Cement Grinding Plant . We take in charge the execution of complete minicement plants and their units.

We are manufacturers and exporters of cement plants like mini cement plant, clinker grinding unit, cement bagging plant ...

(503) Portland Concrete Grinding. Reece Johnson Paving Excavation has 25 years experience, servicing the greater Portland Salem areas

300tpd cement grinding unit cost . 300tpd cement grinding unit cost. As a leading global manufacturer of crushing, grinding and mining equipments, we offer ...

What is Concrete Grinding? Concrete grinding is the process of removing the top layer of concrete with abrasion. In most cases, grinding is done by rotating disks ...

Concrete Grinding Ltd specialises in the upgrade of concrete floors in new existing very narrow aisle warehouses via specialist floor grinding technology

What is concrete grinding? Concrete grinding is a method of repairing uneven concrete surfaces by using the existing concrete slab. FLATLINE CONCRETE GRINDING uses a ...

Description of uses for hand held concrete grinder when preparing to place concrete.

Sika grinding aids can take your grinding and cement performance to the next level for the enhancement of cement performance and grinding efficiency.

Concrete grinder. A concrete grinder can come in many configurations, the most common being a handheld Angle grinder, but it may be a specialized tool for countertops or worktops. There are also purposebuilt floor grinders that are used for grinding and polishing marble, granite and concrete.

Info on concrete grinding machines used for surface prepartion that will help you be a smart shopper. Typical applications, attachment options, and tips for best results.

Grinding Portland cement with a Blaine of 3200 cm 2 /g consumes approximately 23 kWh/t and even for pozzolanic cement with a Blaine of 4000, ...

This article explains what is cement, ... A small amount of gypsum is also added during the final grinding. It is now the finished product – Portland cement.

Concrete grinding is a means of preserving pavement by removing surface irregularities and imperfections. This sometimes includes concrete leveling to make the surface more durable, or the use of a concrete grinder to smooth a rough surface.

Grinders for floor leveling and restoration. You can do many ... Concrete grinding is the simplest and most efficient method for leveling and restoring

Cement Grinding Aids. Cement manufacturing is a highly technical process in which every part has a decisive impact on the product quality as well as on economical and ecological production parameters.

Cement Grinding Unit Stone Quarrying Machine. You Deserve Cement Grinding Unit Cement industry is a traditional high energyconsuming industries, to consider from ...

Colorado Concrete Grinding. Concrete grinding is a great value option to dress up any concrete surface! We are experts in grinding interior concrete floors so that you can apply other flooring systems on a smooth, level surface, OR .

After grinding concrete, your next repair option might be to stain, paint or seal. You can even stain concrete to make it look like luxurious polished stone.

Floor grinding is compared with shot blasting and scarifying. What are the benefits and why is it so much better?

116 of 1,821 results for "concrete grinding wheel" Amazon''s Choice for "concrete grinding wheel" ... Used for heavy duty grinding concrete, mortar to ...

Dec 24, 2010· Concrete floor grinder , an economical concrete floor prep solution featuring a 175 ...

what is grinding in cement Concrete Grinding and Polishing Concrete Floors . Grinding Concrete is the easiest way to .

WhatsApp)

WhatsApp)